Product classification

Contact Us

WhatsApp:

Enterprise Email

Business Address:

No.1, Meishan East Road, Laixi Economic Development Zone, Qingdao City, Shandong Province

Pneumatic butterfly valve

Category:

首页产品展示

Valve series

Nominal pressure: 1.0/1.6/2.0Mpa

Applicable temperature:-10 ℃-150 ℃

Drive mode: handle, turbine, electric, pneumatic

Applicable medium: fresh water, sea water, food, natural gas, alcohol, salt, acid, alkali, oil, steam, air, etc

- 产品描述

- parameter

-

- Commodity name: Pneumatic butterfly valve

Pneumatic butterfly valve Nominal diameter: 50-600(2 "-24")<br>Nominal pressure: 1.0/1.6/2.0Mpa<br>Applicable temperature:-10 ℃-150 ℃<br>Drive mode: handle, turbine, electric, pneumatic<br>Applicable medium: fresh water, sea water, food, natural gas, alcohol, salt, acid, alkali, oil, steam, air, etc<br /></br></br></br></br>

Our company is willing to serve the industry and is ready to supply goods in the shortest possible time according to the requirements of customers. Good communication with customers is thoughtful and meticulous, and we are ready to solve problems for customers on products at any time. For this reason, our company is ready to provide customers with the required services and continuous improvement every day.

We believe that meeting customer requirements is our service tenet; it is our honor to provide quality service to customers; I hope your inquiry, please feel free to contact our business personnel.

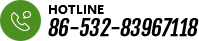

Product Features

--------pneumatic butterfly valve

Nominal diameter:50-600(2”-24”)

Nominal pressure:1.0/1.6/2.0Mpa

Applicable temperature:-10 ℃-150 ℃

Driving mode:Handle, turbine, electric, pneumatic

Applicable medium: fresh water, sea water, food, natural gas, alcohol, salt, acid, alkali, oil, steam, air, etc

Body: Gray cast iron, Ductile iron, Cast steel, Stainless steel

Stem: stainless steel 416, stainless steel 316, stainless steel 304, carbon steel nickel phosphorus plated

Valve plate: stainless steel CF8, stainless steel CF8M, ductile iron nickel phosphorus plated, ductile iron nylon coated, aluminum bronze

Seat: Ding Qing rubber NBR, ethylene propylene rubber EPDM, fluorine rubber VITON, silicone rubber SEP, heat resistant EPDM, wear resistant EPDM, PTFE PTFE

Product Parameters

--------Pathmm

L

National Standard (10/16)

American Standard (150LBS)

Daily Standard (5K/10K)

ΦB

H

H1

G*f/K

J

H2

Z-Φ

ΦD

ΦD1

ΦD2

ΦA

N-M

ΦA

N-M

ΦA

N-M

25

33

85

4-12

79.5

4-14

75/90

4-10/12

55/65

140

46

9.5*7/11

/

15/27

4-5.2/7.5

69

59

34

32

33

100

4-16

88.9

4-14

90/100

4-12/16

140

46

9.5*7/11

/

15/27

4-5.2/7.5

69

59

24

40

33

110

4-16

98.5

4-14

95/105

4-12/16

55/65

147

53

9.5*7/11

/

15/27

4-5.2/7.5

80

68

44

50

42

125

4-16

120.7

4-16

105/120

4-12/16

65/90

195

55

14*10/11

1-3

15/27

4-7.5/10

95

82

55

65

44

145

4-16

139.7

4-16

130/140

4-12/16

65/90

217

64

14*10/11

1-3

15/27

4-7.5/10

114

97

69

80

44

160

8-16

152.4

4-16

145/150

4/8-16

65/90

232

73

14*10/11

1-3

15/27

4-7.5/10

126

113

81

100

50

180

8-16

190.5

8-16

165/175

8-16

90

270

88

16*11/11

1-5

20/27

4-10

154

139

108

125

56

210

8-16

215.9

8-20

200/210

8-16/20

90

292

102

19*12/14

1-5

20/27

4-10

180

163

135

150

56

240

8-20

241.3

8-20

230/140

8-16/20

90

318

115

19**13/14

1-5

20/27

4-10

206

195

154

200

60

295

8-20/12-20

298.5

8-20

280/290

8/12-20

120/150

390

149

22*16/17

1-5

25/40

4-12

264

250

205

250

68

350/355

12-20/12-24

362

12-24

345/355

12-20/22

120/150

457

184

30*22/22

1-8

30/45

4-12

320

305

255

300

78

400/410

12-20/12-24

431.8

12-24

390/400

12-20/16-22

150

518

207

30*22/22

1-8

30/50

4-12/14

270

352

302

350

78

460/470

16-20/16-24

476.3

12-27

435/445

12/16-22

150

610

247

35/27

1-8

35/55

4-12/14

430

405

345

400

102

515/525

16-24/16-27

539.8

16-27

495/510

16-22/24

120/200

650

275

40/27

1-10

35/64

4-14/18

480

455

395

450

114

565/585

20-24/20-27

577.9

16-30

555/565

16-22/20-24

210

713

307

50/36

1-12

50/80

4-18/22

550

515

450

500

127

620/650

20-24/20-30

635

20-30

605/620

20-22/24

210

768

330

50/36

1-12

50/80

4-22

590

565

500

600

151

725/770

20-27/20-33

749.3

20-33

715/730

20-24/24-30

210

919

400

60/46

2-16

50/80

4-22

685

674

585

700

163

840

24-27/24-33

863.6

28-33

820/840

24-24/30

300

1144

520

60/46

2-18

55-82

8-18

787

760

705

800

190

950

24-30/24-36

977.9

28-39

830/850

24/28-30

300

1263

591

60/46

2-20

55-82

8-18

905

878

810

900

203

1050

28-30/28-36

1085.8

32-39

1030/1050

24/28-30

300

1376

656

75/55

2-22

55-118

8-18

970

955

885

Pneumatic butterfly valve overview

--------Extensive field research and state-of-the-art engineering development of this design provides excellent shutoff protection (airtight shutoff) with high CV values. The series 22/23 butterfly valves are manufactured from various materials such as PTFE, stainless steel, UHMWPE and special alloys to suit a wide range of customer needs. As with all of Bray's products, precision manufacturing and superior quality remain key proven long service life records.

American Bray pneumatic butterfly valve seals

(Bidirectional): The reinforced PTFE gasket is placed between the two halves. These seals eliminate contamination from external environmental conditions and potential leak paths from online media.

Pneumatic butterfly valve sealed capsule

This sealed capsule completely isolates the valve body and stem from the in-line media. The sealed capsule is made of pure PTFE closed with internal strength. The capsule fits into the upper and lower disc hubs in the groove process. During assembly and compression between the valve flap and the valve seat, the capsule becomes energized, exerting both upward and downward pressure on the valve flap and valve seat surfaces.

Installation of American Bray Pneumatic Butterfly Valve

● Threaded ports can be provided at the neck of the body below the stem seal to connect a leak detector or instrument.

● The ground wire is provided to prevent static build-up. Install the cable to the valve body.

Ordering instructions:

Customer provides the following product attributes prior to purchase:

1. Product model, connection form, nominal diameter, pressure range and material requirements.

2. If the valve is an imported valve, please inform the valve brand and valve model.

3. Product standards and other instructions.

If the customer has other requirements, please explain them before signing the contract.

If the customer needs help with the selection, * good can provide product requirements, or on-site photos.

After-sales service

--------In line with the service purpose of "user is god", we strictly abide by the quality management procedures and quality assurance department operation determined by ISO9001-2000 world quality system certification, and participate in your company's valve bidding activities. we solemnly promise that we are willing to participate in the competition with first-class and reliable commodity quality, fair and reasonable quotation, outstanding and timely after-sales service, and sincerely serve your users. After the supply, our factory will send professional and technical personnel to debug the equipment of the goods, and provide technical guidance to the buyer's personnel and the protection and maintenance training of the goods.

Product parameters

Our company is willing to serve the industry and is ready to supply goods in the shortest possible time according to the requirements of customers. Good communication with customers is thoughtful and meticulous, and we are ready to solve problems for customers on products at any time. For this reason, our company is ready to provide customers with the required services and continuous improvement every day.

We believe that meeting customer requirements is our service tenet; it is our honor to provide quality service to customers; I hope your inquiry, please feel free to contact our business personnel.

Product Features

--------

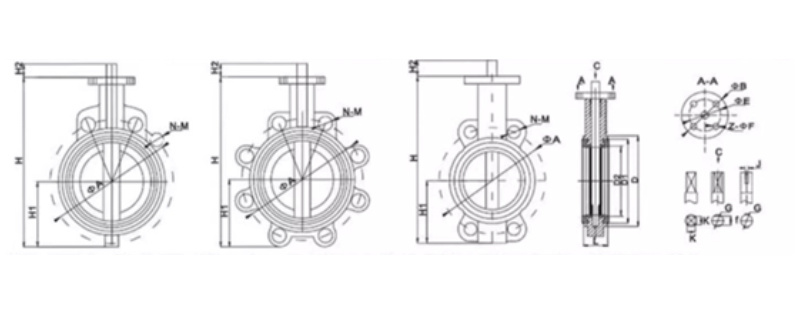

pneumatic butterfly valve

Nominal diameter:50-600(2”-24”)

Nominal pressure:1.0/1.6/2.0Mpa

Applicable temperature:-10 ℃-150 ℃

Driving mode:Handle, turbine, electric, pneumatic

Applicable medium: fresh water, sea water, food, natural gas, alcohol, salt, acid, alkali, oil, steam, air, etc

Body: Gray cast iron, Ductile iron, Cast steel, Stainless steel

Stem: stainless steel 416, stainless steel 316, stainless steel 304, carbon steel nickel phosphorus plated

Valve plate: stainless steel CF8, stainless steel CF8M, ductile iron nickel phosphorus plated, ductile iron nylon coated, aluminum bronze

Seat: Ding Qing rubber NBR, ethylene propylene rubber EPDM, fluorine rubber VITON, silicone rubber SEP, heat resistant EPDM, wear resistant EPDM, PTFE PTFE

Product Parameters

--------

| Pathmm |

L |

National Standard (10/16) |

American Standard (150LBS) |

Daily Standard (5K/10K) |

ΦB |

H |

H1 |

G*f/K |

J |

H2 |

Z-Φ |

ΦD |

ΦD1 |

ΦD2 |

|||

| ΦA |

N-M |

ΦA |

N-M |

ΦA |

N-M |

||||||||||||

| 25 |

33 |

85 |

4-12 |

79.5 |

4-14 |

75/90 |

4-10/12 |

55/65 |

140 |

46 |

9.5*7/11 |

/ |

15/27 |

4-5.2/7.5 |

69 |

59 |

34 |

| 32 |

33 |

100 |

4-16 |

88.9 |

4-14 |

90/100 |

4-12/16 |

|

140 |

46 |

9.5*7/11 |

/ |

15/27 |

4-5.2/7.5 |

69 |

59 |

24 |

| 40 |

33 |

110 |

4-16 |

98.5 |

4-14 |

95/105 |

4-12/16 |

55/65 |

147 |

53 |

9.5*7/11 |

/ |

15/27 |

4-5.2/7.5 |

80 |

68 |

44 |

| 50 |

42 |

125 |

4-16 |

120.7 |

4-16 |

105/120 |

4-12/16 |

65/90 |

195 |

55 |

14*10/11 |

1-3 |

15/27 |

4-7.5/10 |

95 |

82 |

55 |

| 65 |

44 |

145 |

4-16 |

139.7 |

4-16 |

130/140 |

4-12/16 |

65/90 |

217 |

64 |

14*10/11 |

1-3 |

15/27 |

4-7.5/10 |

114 |

97 |

69 |

| 80 |

44 |

160 |

8-16 |

152.4 |

4-16 |

145/150 |

4/8-16 |

65/90 |

232 |

73 |

14*10/11 |

1-3 |

15/27 |

4-7.5/10 |

126 |

113 |

81 |

| 100 |

50 |

180 |

8-16 |

190.5 |

8-16 |

165/175 |

8-16 |

90 |

270 |

88 |

16*11/11 |

1-5 |

20/27 |

4-10 |

154 |

139 |

108 |

| 125 |

56 |

210 |

8-16 |

215.9 |

8-20 |

200/210 |

8-16/20 |

90 |

292 |

102 |

19*12/14 |

1-5 |

20/27 |

4-10 |

180 |

163 |

135 |

| 150 |

56 |

240 |

8-20 |

241.3 |

8-20 |

230/140 |

8-16/20 |

90 |

318 |

115 |

19**13/14 |

1-5 |

20/27 |

4-10 |

206 |

195 |

154 |

| 200 |

60 |

295 |

8-20/12-20 |

298.5 |

8-20 |

280/290 |

8/12-20 |

120/150 |

390 |

149 |

22*16/17 |

1-5 |

25/40 |

4-12 |

264 |

250 |

205 |

| 250 |

68 |

350/355 |

12-20/12-24 |

362 |

12-24 |

345/355 |

12-20/22 |

120/150 |

457 |

184 |

30*22/22 |

1-8 |

30/45 |

4-12 |

320 |

305 |

255 |

| 300 |

78 |

400/410 |

12-20/12-24 |

431.8 |

12-24 |

390/400 |

12-20/16-22 |

150 |

518 |

207 |

30*22/22 |

1-8 |

30/50 |

4-12/14 |

270 |

352 |

302 |

| 350 |

78 |

460/470 |

16-20/16-24 |

476.3 |

12-27 |

435/445 |

12/16-22 |

150 |

610 |

247 |

35/27 |

1-8 |

35/55 |

4-12/14 |

430 |

405 |

345 |

| 400 |

102 |

515/525 |

16-24/16-27 |

539.8 |

16-27 |

495/510 |

16-22/24 |

120/200 |

650 |

275 |

40/27 |

1-10 |

35/64 |

4-14/18 |

480 |

455 |

395 |

| 450 |

114 |

565/585 |

20-24/20-27 |

577.9 |

16-30 |

555/565 |

16-22/20-24 |

210 |

713 |

307 |

50/36 |

1-12 |

50/80 |

4-18/22 |

550 |

515 |

450 |

| 500 |

127 |

620/650 |

20-24/20-30 |

635 |

20-30 |

605/620 |

20-22/24 |

210 |

768 |

330 |

50/36 |

1-12 |

50/80 |

4-22 |

590 |

565 |

500 |

| 600 |

151 |

725/770 |

20-27/20-33 |

749.3 |

20-33 |

715/730 |

20-24/24-30 |

210 |

919 |

400 |

60/46 |

2-16 |

50/80 |

4-22 |

685 |

674 |

585 |

| 700 |

163 |

840 |

24-27/24-33 |

863.6 |

28-33 |

820/840 |

24-24/30 |

300 |

1144 |

520 |

60/46 |

2-18 |

55-82 |

8-18 |

787 |

760 |

705 |

| 800 |

190 |

950 |

24-30/24-36 |

977.9 |

28-39 |

830/850 |

24/28-30 |

300 |

1263 |

591 |

60/46 |

2-20 |

55-82 |

8-18 |

905 |

878 |

810 |

| 900 |

203 |

1050 |

28-30/28-36 |

1085.8 |

32-39 |

1030/1050 |

24/28-30 |

300 |

1376 |

656 |

75/55 |

2-22 |

55-118 |

8-18 |

970 |

955 |

885

|

Pneumatic butterfly valve overview

--------

Extensive field research and state-of-the-art engineering development of this design provides excellent shutoff protection (airtight shutoff) with high CV values. The series 22/23 butterfly valves are manufactured from various materials such as PTFE, stainless steel, UHMWPE and special alloys to suit a wide range of customer needs. As with all of Bray's products, precision manufacturing and superior quality remain key proven long service life records.

American Bray pneumatic butterfly valve seals

(Bidirectional): The reinforced PTFE gasket is placed between the two halves. These seals eliminate contamination from external environmental conditions and potential leak paths from online media.

Pneumatic butterfly valve sealed capsule

This sealed capsule completely isolates the valve body and stem from the in-line media. The sealed capsule is made of pure PTFE closed with internal strength. The capsule fits into the upper and lower disc hubs in the groove process. During assembly and compression between the valve flap and the valve seat, the capsule becomes energized, exerting both upward and downward pressure on the valve flap and valve seat surfaces.

Installation of American Bray Pneumatic Butterfly Valve

● Threaded ports can be provided at the neck of the body below the stem seal to connect a leak detector or instrument.

● The ground wire is provided to prevent static build-up. Install the cable to the valve body.

Ordering instructions:

Customer provides the following product attributes prior to purchase:

1. Product model, connection form, nominal diameter, pressure range and material requirements.

2. If the valve is an imported valve, please inform the valve brand and valve model.

3. Product standards and other instructions.

If the customer has other requirements, please explain them before signing the contract.

If the customer needs help with the selection, * good can provide product requirements, or on-site photos.

After-sales service

--------

In line with the service purpose of "user is god", we strictly abide by the quality management procedures and quality assurance department operation determined by ISO9001-2000 world quality system certification, and participate in your company's valve bidding activities. we solemnly promise that we are willing to participate in the competition with first-class and reliable commodity quality, fair and reasonable quotation, outstanding and timely after-sales service, and sincerely serve your users. After the supply, our factory will send professional and technical personnel to debug the equipment of the goods, and provide technical guidance to the buyer's personnel and the protection and maintenance training of the goods.

Keywords: precision steel casting series | valve series | flange valve series

Related products

Product message

Qingdao Xingute Metal Manufacturing Co., Ltd

WhatsApp: +86-15092035603

Enterprise Email: xgtmetal@xgtcasting.com

Address: No.1, Meishan East Road, Laixi Economic Development Zone, Qingdao City, Shandong Province

Customer Message

Copyright©2023 Qingdao Xingute Metal Manufacturing Co., Ltd SEO Business License